UniTech Aero Industries

Frequently Asked Questions (FAQs)

What services does UniTech Aero Industries provide?

UniTech Aero Industries specializes in:

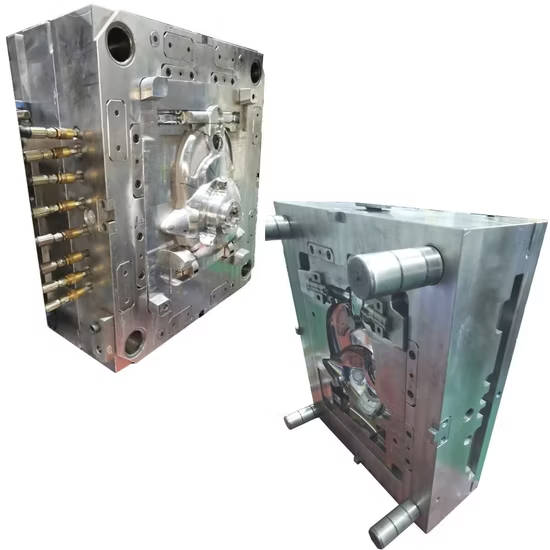

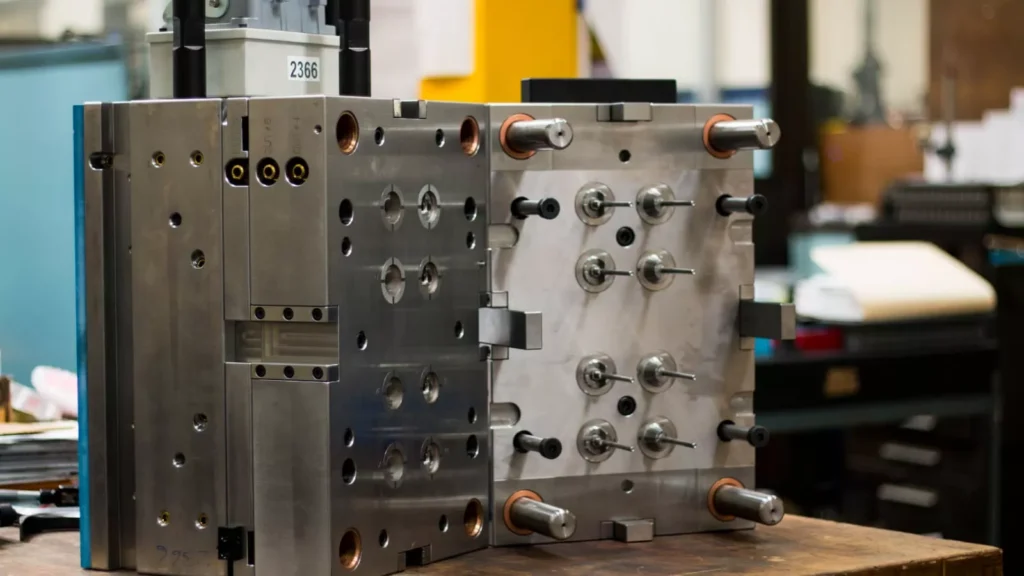

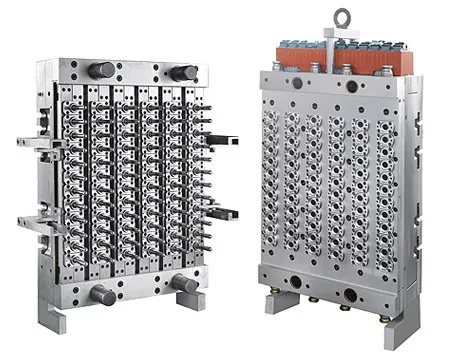

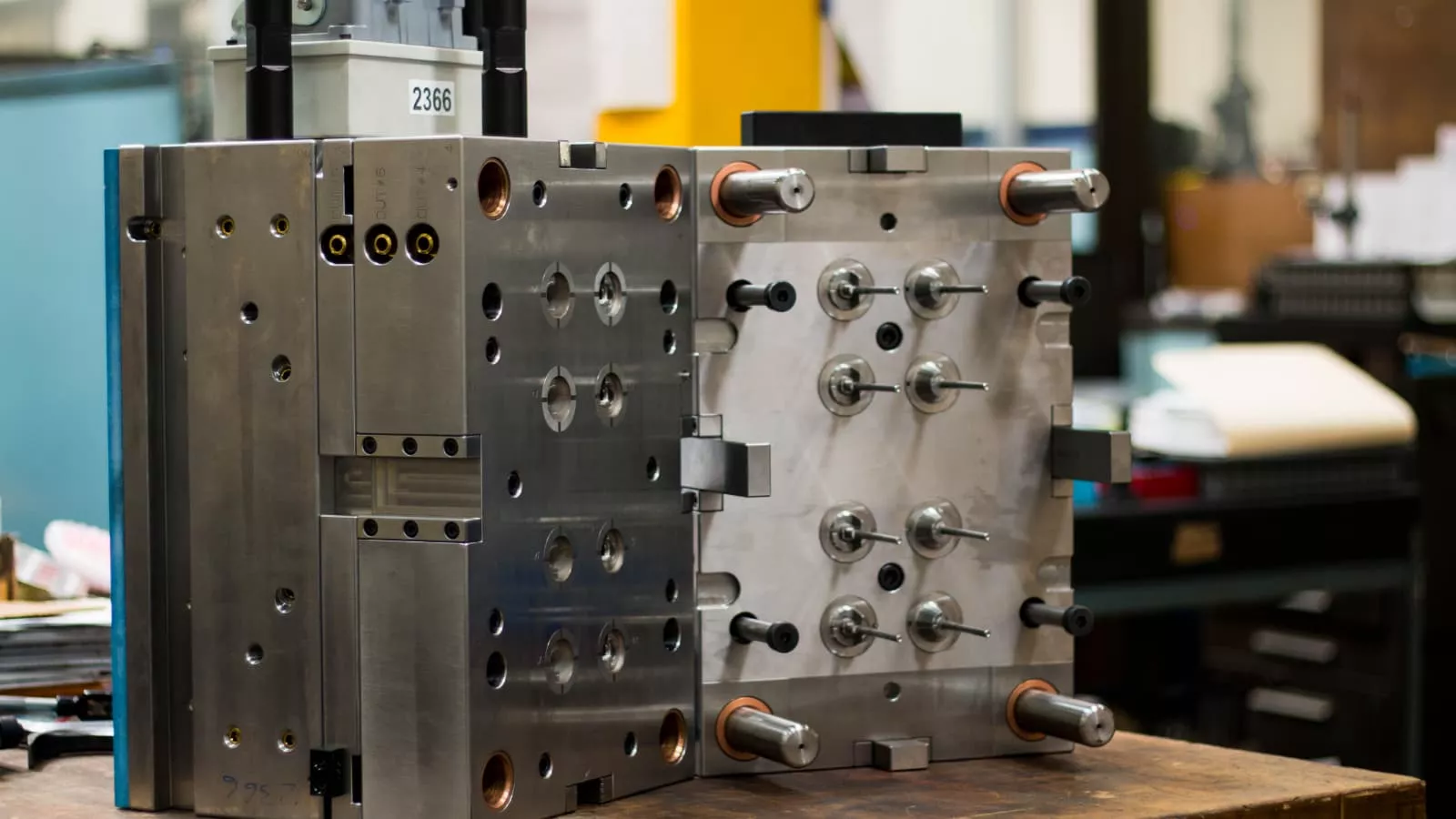

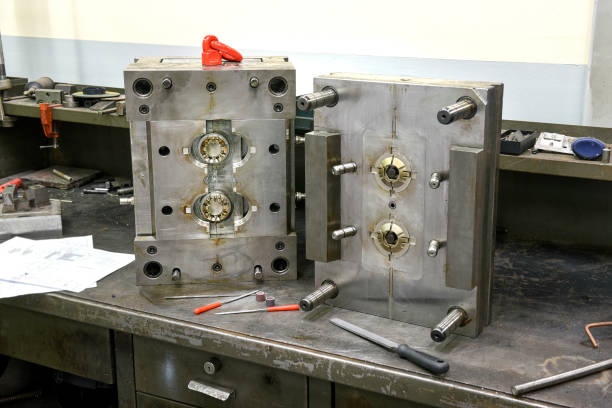

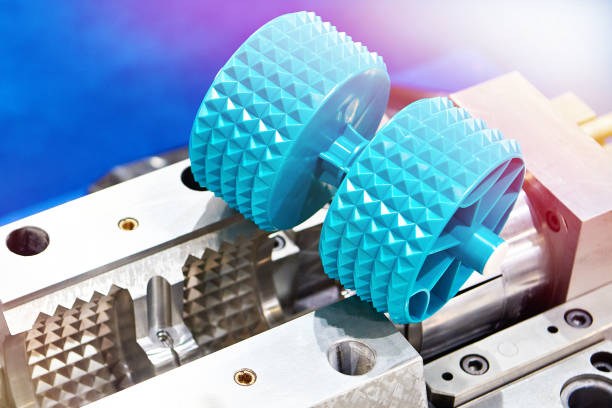

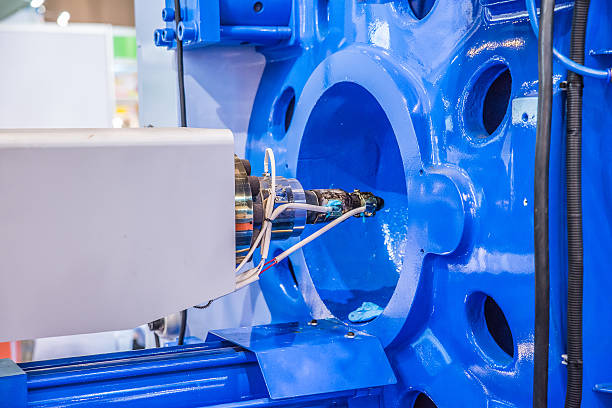

Manufacturing high-quality plastic injection molding parts for various industries.

UniTech Aero Industries specializes in:

Manufacturing high-quality plastic injection molding parts for various industries.

UniTech Aero Industries specializes in:

Manufacturing high-quality plastic injection molding parts for various industries.

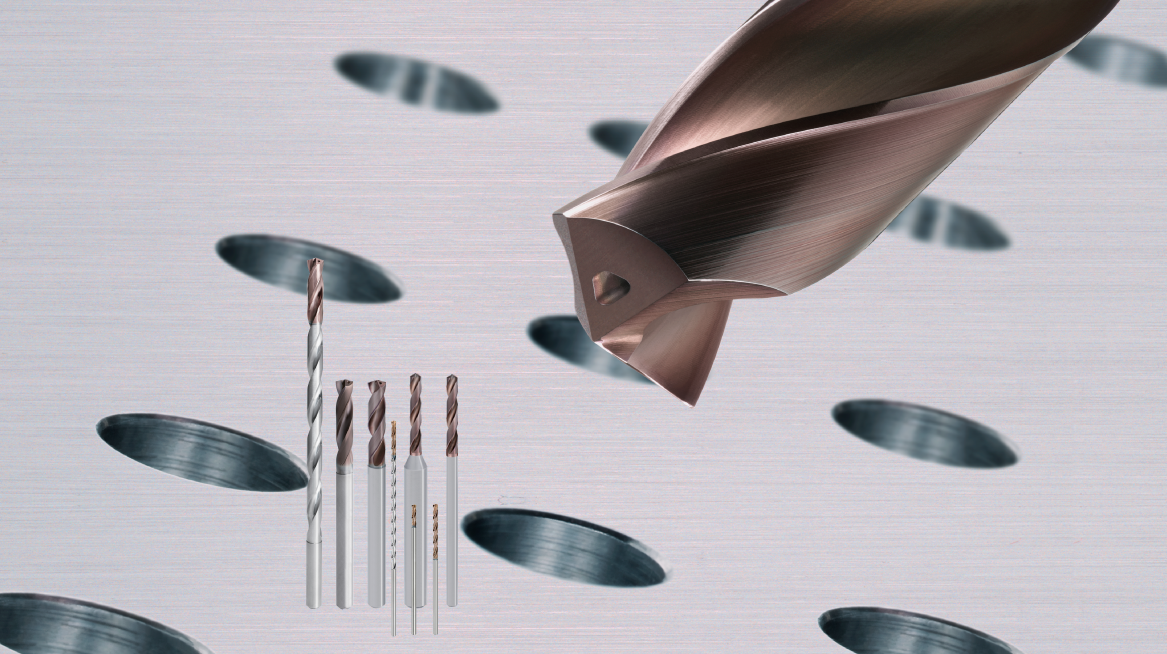

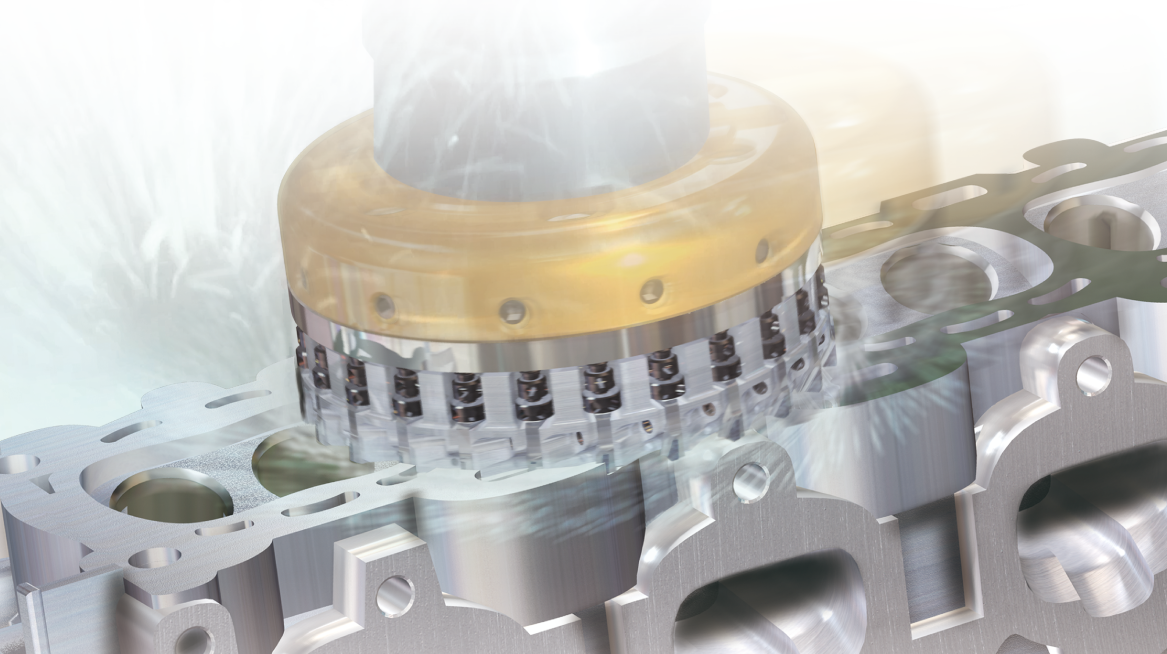

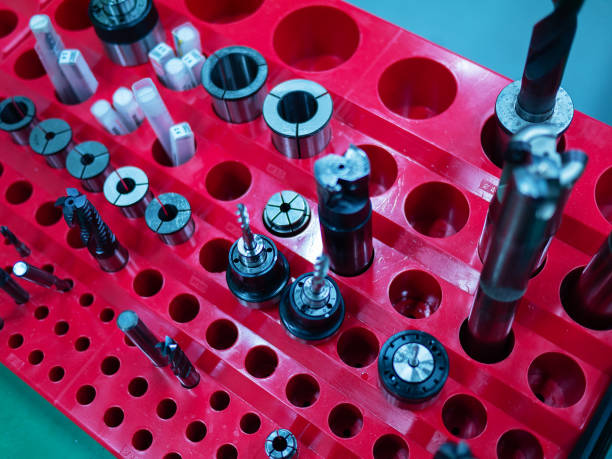

Trading and supplying cutting tools for precision machining applications.

Which industries do you serve?

We cater to a wide range of industries, including:

Automotive

Oil & Energy

Electronics

Medical

Furniture

Machine Building

Toys and Other Specialized Industries

What types of plastic injection molding parts do you manufacture?

We manufacture a variety of precision-moulded plastic parts used in:

Automotive components

Electrical enclosures

Medical device housings

Furniture parts

Machine components

Toy parts

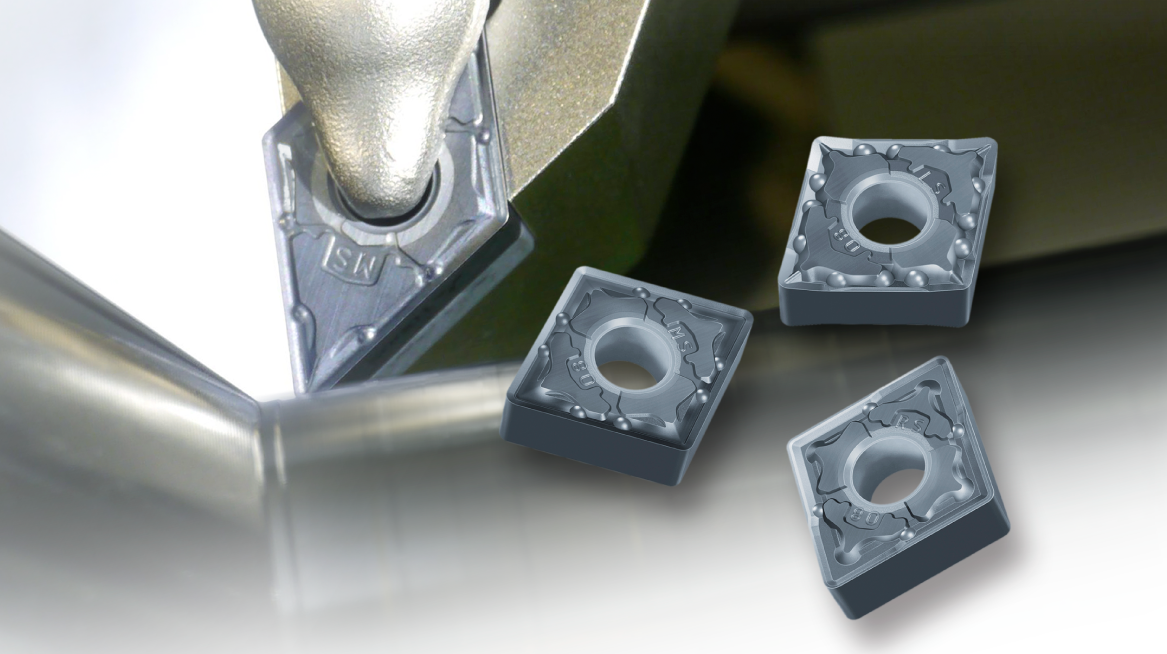

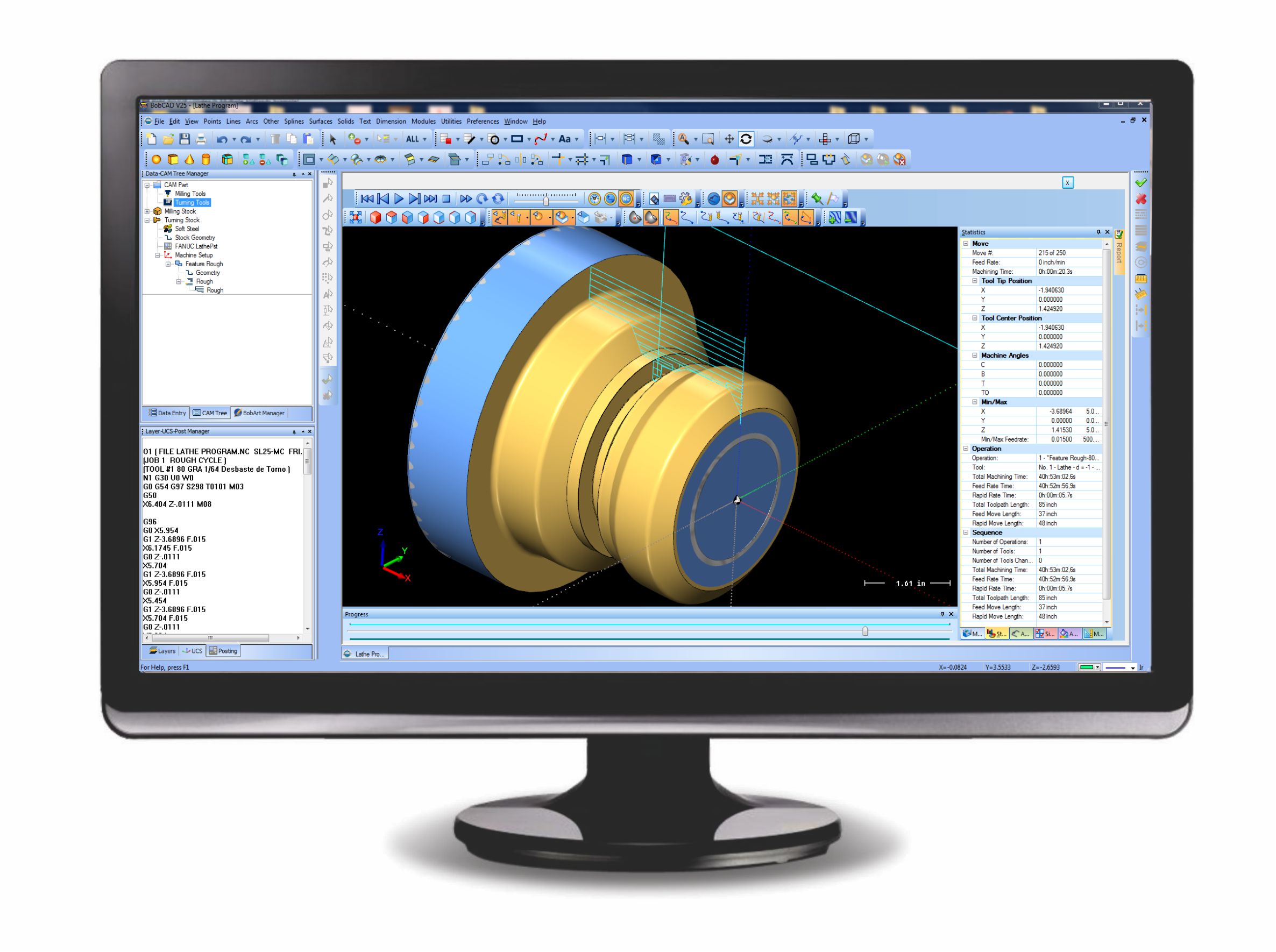

What types of cutting tools do you supply?

We offer a wide range of high-precision cutting tools, including:

Carbide Tools

High-Speed Steel (HSS) Tools

Drills and End Mills

Reamers and Inserts

Custom Cutting Solutions